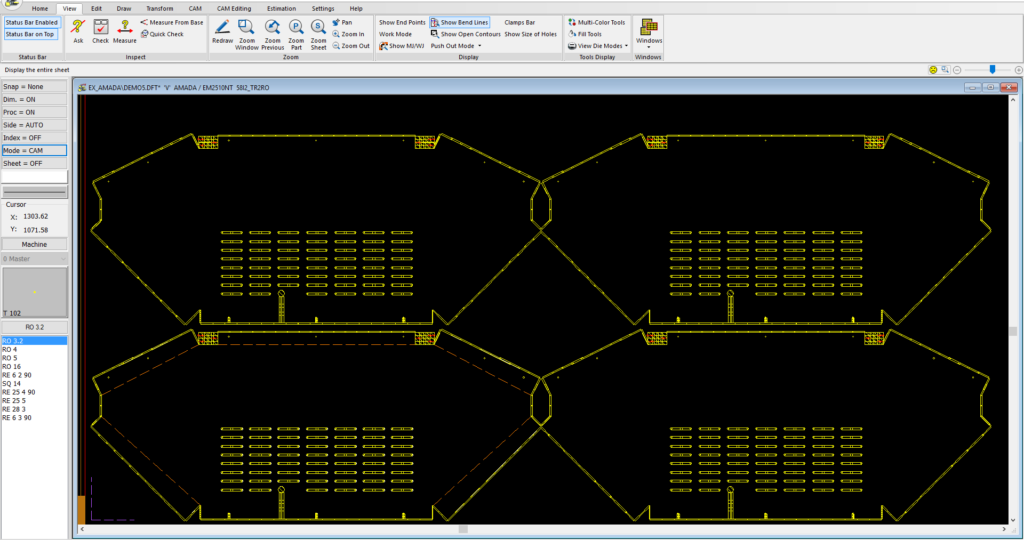

cncKad punching creates programs for your punch machine from CAM files and designs.

“After testing various software platforms, we very quickly found that the Metalix software suite is a very powerful piece of software and fits very easily into our workflow. It allows us to rapidly go from design to cutting and punching of parts.”

Henk Van Nierkerk and Derrick Van Nierkerk, Directors, METALFORMERS Pty. Ltd., South Africa

cncKad punch turns CAM files into NC code for your punch machine. You can generate efficient programs for your machine with just a few clicks, while optimizing material utilization and machine run time.

Punching in cncKad includes fully automated processing as well as full manual control over all aspects of processing. For example, cncKad automatically chooses tools to process your parts, using factors such as preferred tools, minimizing turret rotation or tool changes, MicroJoints and, of course, material parameters. You can also modify the proposed tool selection as required.

Common cuts, working in stripes, punching part-by-part, and other specific ways of processing the sheet are available. Repositions are calculated automatically, whether to avoid clamp dead zones or to process sheets larger than the working range of the machine.

cncKad always optimizes the chosen methods to minimize production time, taking machine capabilities and limitations into account. The post-processor then converts these actions into efficient NC programs.

Punch features include:

• Automatic punching

• WireJoints and MicroJoints

• Predefined Shapes

• Special Processing

• Common cuts

• Sheet trimming

• Processing stripes

• Turret setup customization

• Sheet repositions

• Automatic Indexing

• Special tools

• Clamp avoidance