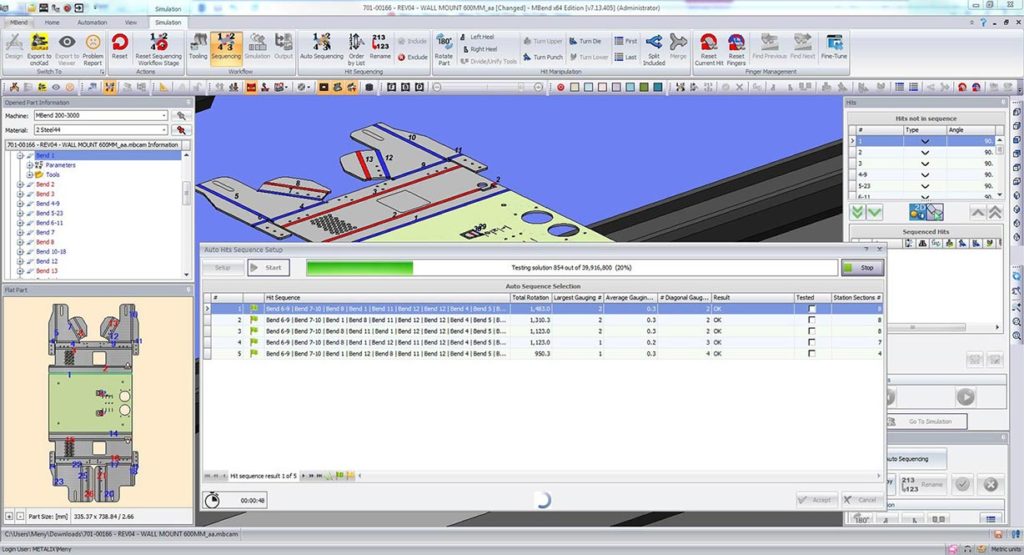

MBend enables manual selection or automatic calculation of bend sequencing.

“Our new upgrade was up and running less than four minutes after installation. I am very satisfied with the new features and quality code.”

Mitchell Parlette, Allfab, Inc., USA

MBend automatic sequence setting capabilities:

- Calculation of a collision-free sequence for any number of bends

- Optimized tool station setup calculation based on tool segment availability

- Intelligent tool segment distribution and clamping

- Heel tools for overhanging flanges

- Tool rotation (when possible) to avoid part rotations

- Hit splitting to avoid holder and table collisions

- Hemming bends

- Divide and merge tools for collinear (in-line) bends

Automatic Sequencing

After tool selection, MBend can automatically calculate bend sequences, based on different properties of the hits. You can choose the sequence that meets your requirements.

MBend calculates collision-free bending solutions that are ready for production, ensuring the machine operator does not waste time and material on trial runs. If a collision-free bending sequence exists, MBend can find it.

Manual Sequencing in 3D

MBend enables full manual control of bending sequences:

- Set the bend sequence by folding the bends into the finished product

- Split bends into partial bends to avoid collisions

- Change sequences by dragging and dropping single and multiple bends into the order you want

- Use heels/horns

- Rotate the part or the tools

This video sets a bending sequence manually using interactive sequencing