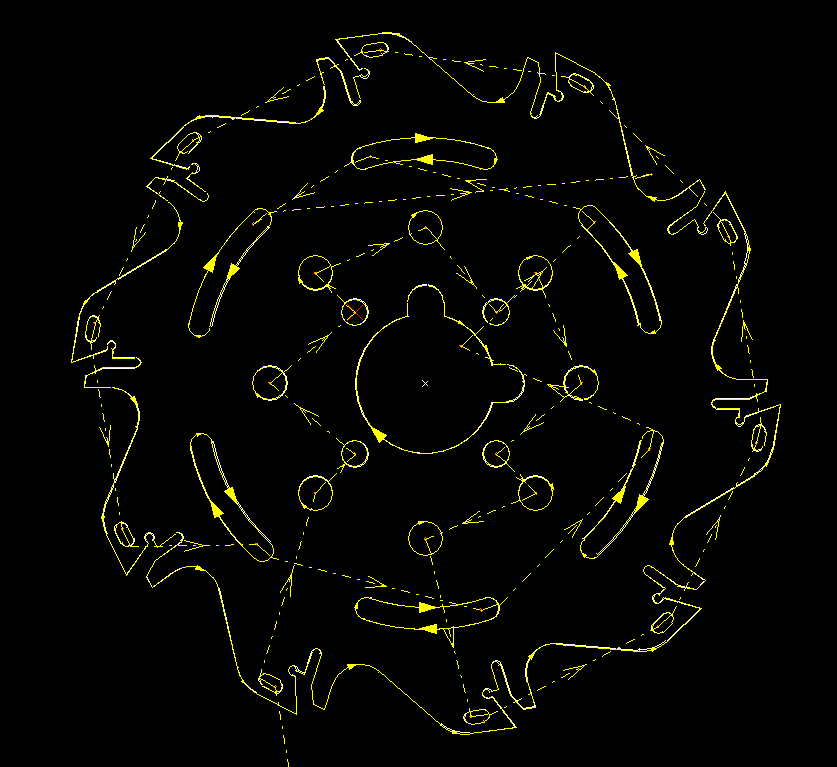

cncKad cutting creates programs for your cutting machine from CAM files and designs.

cncKad cutting turns CAM files into NC code for your cutting machine. In a few clicks you are able to generate efficient programs while optimizing material utilization and machine runtime.

The cutting solution can be influenced by factors such as head, gas, lens, corner treatment, cutting optimization, and MicroJoints. You can modify the proposed parameters and edit the cutting tables as required.

You can easily control common line cutting, cutting part-by-part, cutting order, and any other specific way of processing the sheet.

cncKad always optimizes the chosen methods to minimize the production time, taking machine capabilities and limitations into account. The post-processor then converts these actions into efficient NC programs.

Cutting features include:

• Automatic cutting

• Material-based cutting parameters

• Collision avoidance between cutting head and sheet

• Defining beam width and auto compensation

• Corner treatment

• Z axis control

• Full support for common cuts

• Cutting speeds determined by geometry and material

• WireJoint, MicroJoint, and MicroWeld support

• Vaporization options

• Marking and/or engraving before cutting

• Bridge cutting and chains

• Support for multi-head plasma, flame, and water jet machines