Sheet Metal Processing

To achieve good use rate of materials, we apply the auto layout function in cncKad with AutoNest Pro. The results are always marvelous—the joints generated during the common cut avert any collision between laser cut heads and materials.

Mr. Jian-Yuan Wang, Manager, Jaw Hwa, Taiwan

Metalix supports most sheet metal processing technologies and updates its software in accordance with advances in the industry.

Water Jet

Water cutting machines are easily operated and automated using the cncKad system.

Water-oriented features include bridge cutting, chain cutting, and CCW/CW cutting directions.

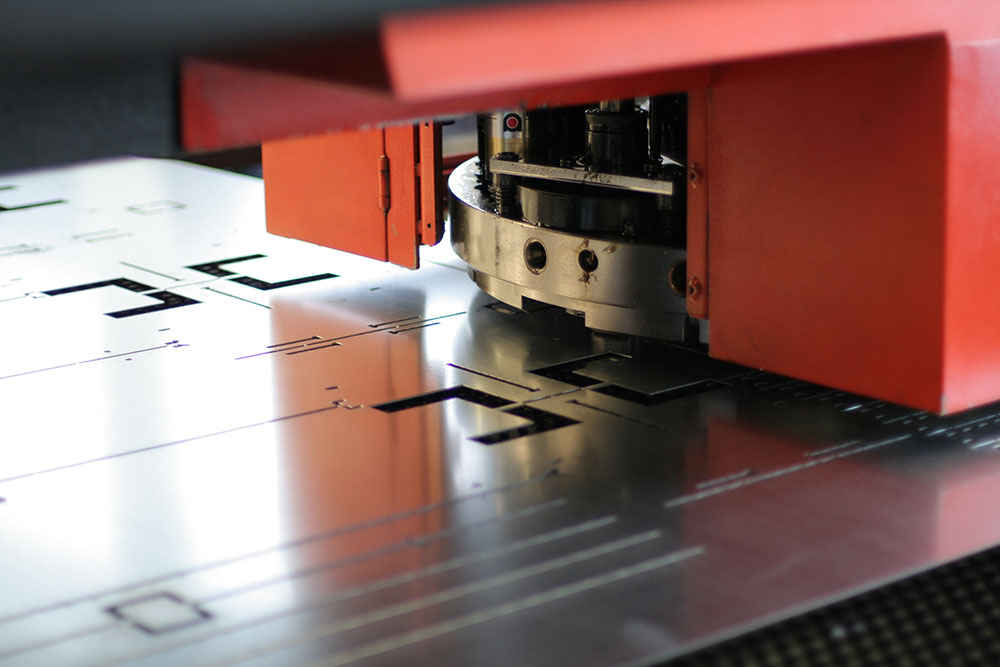

Punch

cncKad for punching + AutoNest is your best solution for manufacturing with punch machines.

cncKad for punching supports:

• Automatic tooling

• Automatic repositions for working range and clamp avoidance

• Automatic part handling:

• MicroJoints

• Chute

• Pickup with vacuum

• Support for advanced tooling, including forming, tapping, wheels, marking, deburring

• Automatic common cuts

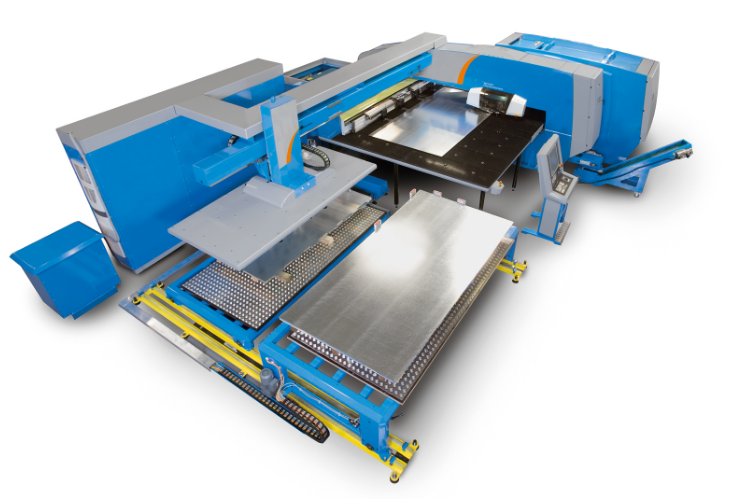

Punch + Cut

Parts processed with cncKad for punch + laser/plasma machines are automatically tooled and optimally nested.

AutoNest Pro gives the best nesting in the industry, while considering tooling and turrets and maximizing common cuts.

Punch + Shear

Shearing allows you to cut your sheet with scissors; i.e., with two blades positioned at a 90° angle. After cncKad processes your parts with internal shapes, chamfered entities, etc., you can shear your sheet:

• Choose between single hit and long cut, with or without clamp reposition.

• Shear horizontally or vertically, or allow cncKad to select the best option.

• Determine the bin number for the scrap or part yourself, or allow cncKad to deposit the instances of your parts automatically in a bin.